Sustainable supply chain management practice is a series of actions that incorporate environmental sustainability and social feedback while maintaining organizational economics in traditional supply chains, including both internal and external company practices, which can achieve true sustainability in supply chains from environmental, social, and economic aspects. The implementation scope of sustainable supply chain management practices ranges from green procurement to product lifecycle management, flowing through suppliers, manufacturers, and customers. This approach enhances partner relationships by improving the flow of goods and information, as well as promoting sustainable practical actions.

According to the latest global CEO survey by PwC, supply chain disruption is one of the top 10 threats to enterprises. Over 50% of CEOs have begun to adjust supply chain management and procurement strategies. Sustainable supply chain has become an important part of enterprise practice for continuous operations. Procurement management is a key mechanism for enterprises to fulfill social responsibility and drive the supply chain to achieve sustainable goals. The U.S. National Institute of Standards and Technology (NIST 800-161) includes sustainability as a key issue in supply chain risk management practices.

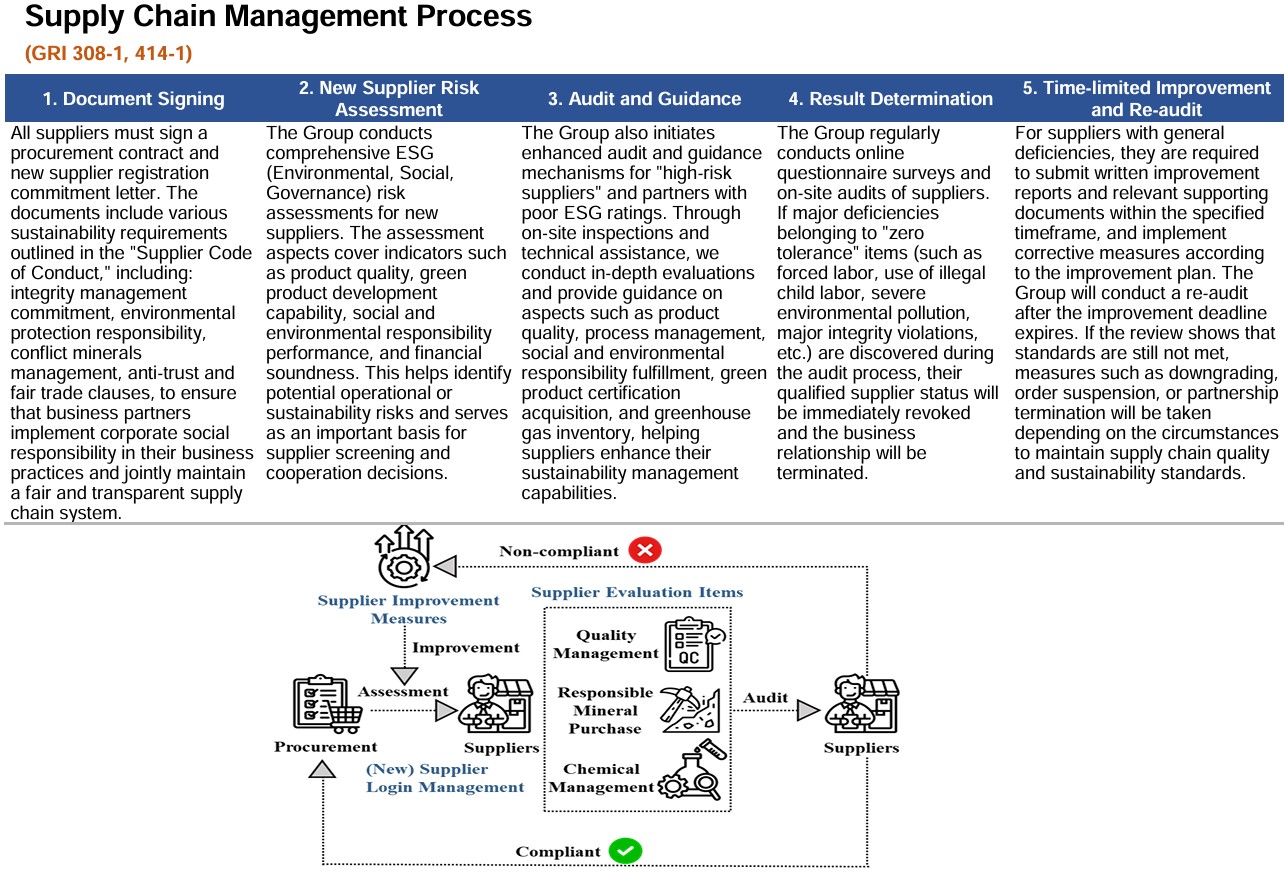

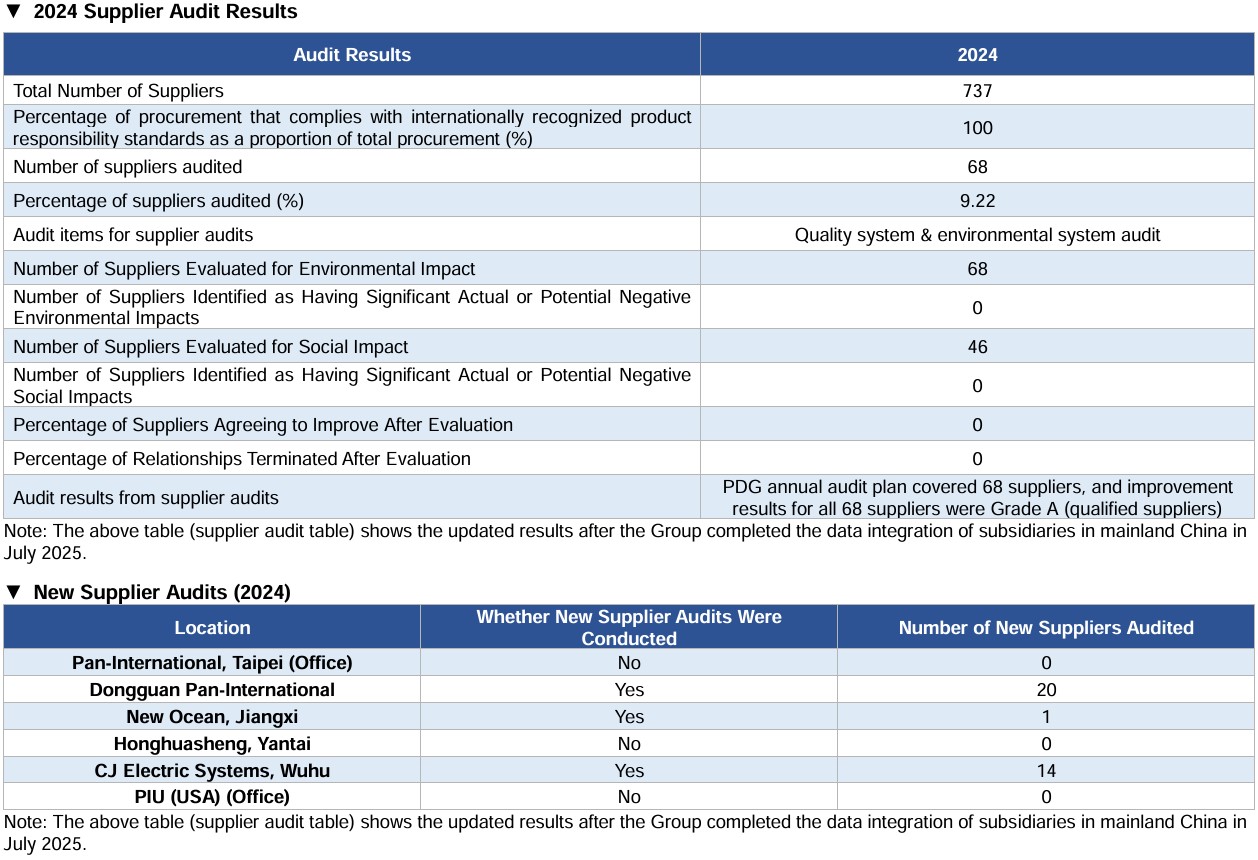

The Group has established a sustainable supply chain management mechanism focusing on three major aspects: product quality, legal compliance, and social responsibility. We have formulated requirements and evaluation standards for operating conditions, manufacturing and supply capabilities, technology development capabilities, quality assurance capabilities, management system performance, environmental management capabilities and trade security. New suppliers must pass an evaluation to be registered on the "Qualified Supplier List." Additionally, suppliers are randomly inspected each year to ensure they continue to meet our evaluation standards. Only those confirmed to pass the evaluation eligible for continued cooperation. We aim to improve supply chain management through pre-assessment, supplier commitments, and regular audits. In addition, considering ESG trends, besides corporate governance and environmental sustainability, employee rights are also a crucial aspect. We will reference international standards such as the "United Nations Guiding Principles on Business and Human Rights," the International Labour Organization's "Declaration on Fundamental Principles and Rights at Work," and the "Universal Declaration of Human Rights," as well as local labor laws in various regions. We will gradually require all suppliers to ensure their business practices in areas such as labor rights, health and safety, and employee benefits comply with the Group's guidelines and commitment letters, and fully comply with the legal regulations in their operating regions.

The Group is committed to practicing corporate social responsibility and aims to expand partnerships with suppliers that closely cooperate in our business. We are gradually integrating corporate social responsibility terms into our supplier contracts, with the long-term goal of requiring 100% of suppliers to fulfill ESG clauses. If suppliers violate the terms of agreement, we will require them to make improvements within a specified timeframe. Those with serious violations may have their cooperation terminated and dissolved. We actively communicate and share information related to social responsibility with our suppliers, encouraging them to develop materials that reduce environmental impact, or to implement energy saving and carbon reduction measures in their processes or equipment, thereby creating a win-win partnership.

When selecting suppliers, our plants set scoring indicators based on quality, price, environmental accreditation, pollution incidents, labor dispute incidents, non-use of child labor, corruption/bribery incidents, and ethical management. We conduct a strict review process, allowing only qualified suppliers to provide samples for testing.

Additionally, before signing contracts and formally supplying, suppliers must sign commitment letters on related topics such as integrity and ethics, environmental issues, and material composition declarations, demonstrating their commitment to honest business operations and environmental sustainability.

Furthermore, Pan-International conducts regular annual supplier conventions to reinforce awareness of business integrity, legal compliance, anti-corruption measures, and the responsible sourcing of minerals, avoiding conflict or high-risk materials.

Through these continuous engagements, the Company fosters a unified commitment within the supply chain and promotes higher ethical standards among suppliers.

<< Detailed information can be found in the latest ESG Sustainability Report, Section: Sustainable Supply Chain >>

Put an end to corruption, discrimination and unfair behavior in the procurement process, suppliers should sign a "Vendor Commitment Letter", promise to abide by the principles of fairness, equity and openness in the transaction process to prevent procurement fraud, and establish an honest, fair and transparent enterprise culture and business policy.

The company will never purchase and use "conflict and high-risk minerals" that mined refer to high-risk/conflict areas listed by the OECD (EX: in the Democratic Republic of the Congo and its surrounding countries and regions), and require suppliers to also comply This Statement and Governing Principles.

Environmental regulations: In response to the EU’s extension of the RoHS Directive (EU)/2015/863 RoHS 2.0 on hazardous substances management for the four new plasticizer hazardous substances (BBP/ DBP/ DEHP/ DIBP) that came into effect in July 2019, the Group Important subsidiaries (with production plants) have also formulated RoHS phosphine (including RoHS 2.0) & other hazardous substance management policies to comprehensively monitor raw materials, packaging materials, auxiliary materials, equipment, treatment tools and related consumables that may contain hazardous substances, and increase employee Relevant training is provided to strengthen the ability to monitor hazardous substances, and all suppliers are required to fully cooperate to meet regulatory specifications and customer standards.

RoHS Cadmium Cd <100 ppm

RoHS Lead Pb <1000 ppm

RoHS Mercury Hg <1000 ppm

RoHS Hexavalent Chromium (Cr+6) <1000 ppm

RoHS PBBs <1000 ppm

RoHS PBDEs <1000 ppm

RoHS 2.0 BBP <1000 ppm

RoHS 2.0 DBP <1000 ppm

RoHS 2.0 DIBP <1000 ppm

RoHS 2.0 DEHP <1000 ppm

other Prohibited and Restricted Substances